DMU 75 monoBlock

working range:

X-Axis 750 mm

Y-Axis 650 mm

Z-Axis 560 mm

Tisch / NC-rotary attachment: Ø 650 mm / 650 mm x 650 mm

Load on attachment: 600 kg

5-Axix Deckel Maho DMU 80P Duo Block

working range:

- X-Axis 800 mm

- Y-Axis 1.050 mm

- Z-Axis 850 mm

NC-rotary attachment: Ø 900 mm x 700 mm

Load on attachment: 1.800 kg

40-fold tool charger

5-Axis Deckel Maho DMU 85 mono Block

working range:

- X-Axis 1.000 mm

- Y-Axis 710 mm

- Z-Axis 710 mm

NC-rotary attachment: Ø 850 mm / 1.000 mm x 750 mm

Load on attachment: 1.500 kg

30-fold tool charger

slewing area: C-Achse 360°

swivel range: A-Achse 120 / +120°

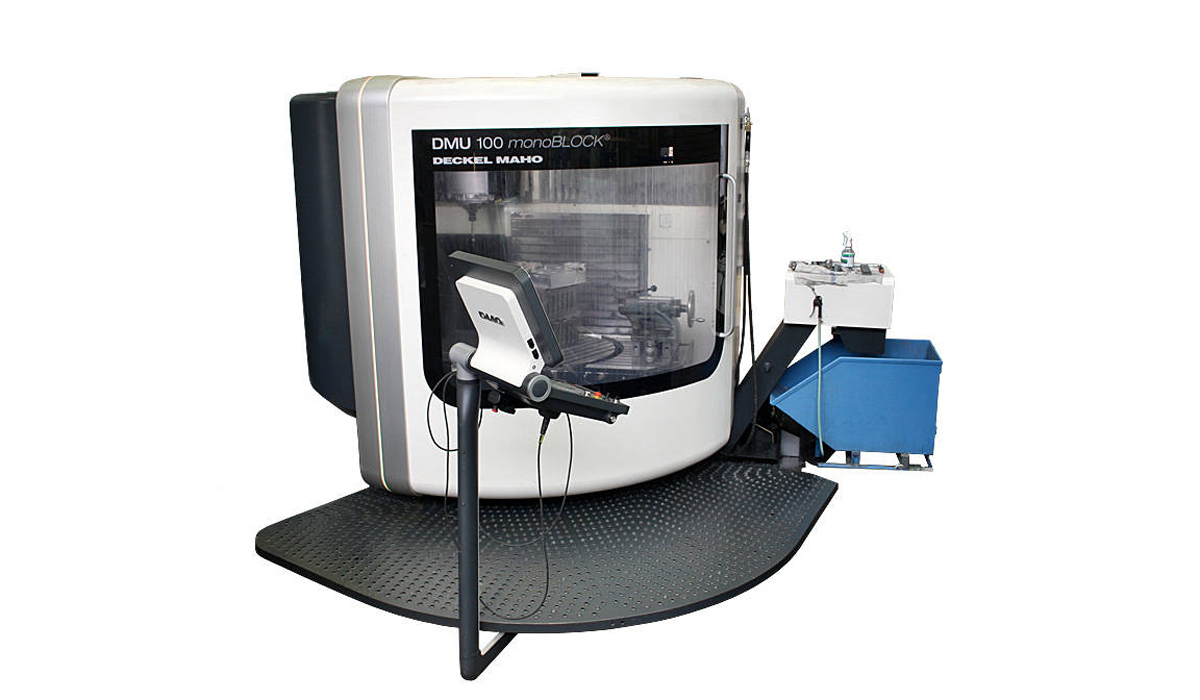

5-Axis Deckel Maho DMU 100 mono Block

working range

- X-Axis 1.000 mm

- Y-Axis 710 mm

- Z-Axis 710 mm

NC-rotary attachment: Ø 800 mm / 1.500 mm x 800 mm

Load on attachment: 800 kg

B-Axis

32-fold tool charger

5-Axis Deckel Maho DMU 100 mono Block

working range

- X-Axis 1.000 mm

- Y-Axis 710 mm

- Z-Axis 710 mm

NC-rotary attachment: Ø 800 mm / 1.500 mm x 800 mm

60-fold tool charger

Load on attachment: 800 kg

B-Axis

5-Achs Deckel Maho DMU 105 mono Block

Arbeitsbereiche

- X-Axis 1.200 mm

- Y-Axis 850 mm

- Z-Axis 810 mm

NC-rotary attachment: Ø 1050 mm / 1.250 mm x 850 mm

Load on attachment: 1.500 kg

60-fold tool charger

4-Axis Deckel Maho DMU 125 P Duo Block

working range

- X-Axis 1.250 mm

- Y-Axis 1.000 mm

- Z-Axis 1.000 mm

NC-rotary attachment: Ø 1.200 mm

40-fold tool charger

Load on attachment: 2.500 kg

Milling machine 5 - Axis Hermle C50

working range

X-Axis 1000 mm

Y-Axis 1110 mm

Z-Axis 750 mm

NC-rotary attachment: Ø 700 mm / 1150 mm x 900 mm

Load on attachment: 2.000 kg

60-fold tool charger

C – Axis 360°

A - Axis -130 / + 100

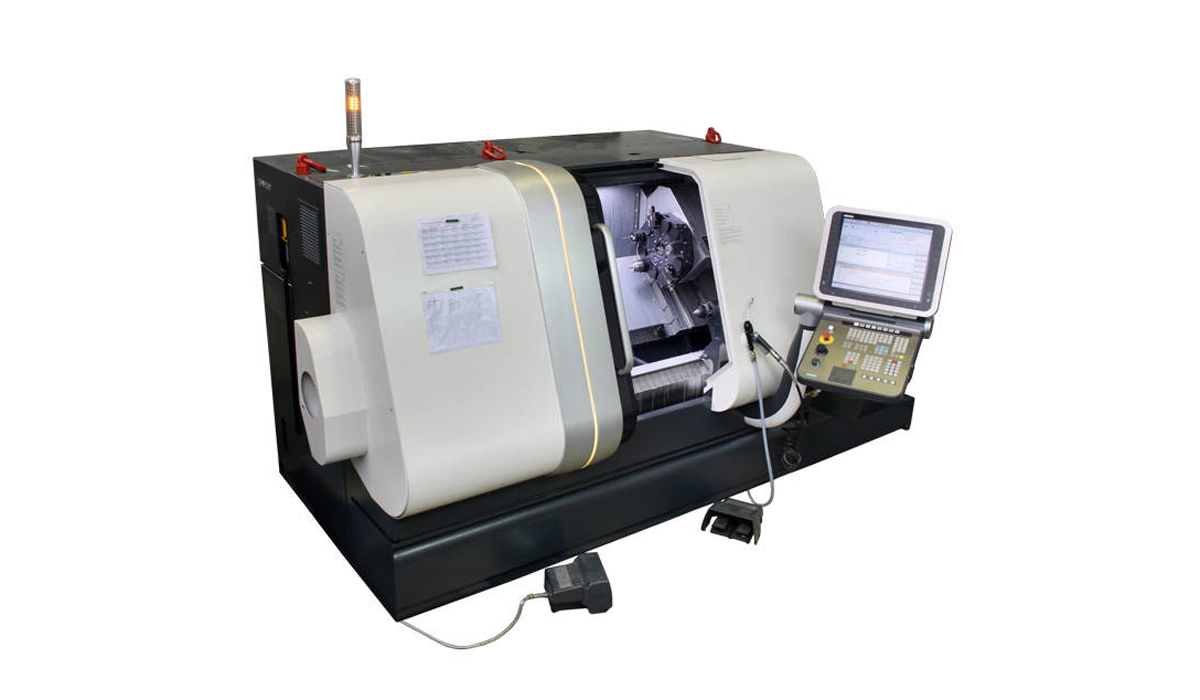

DMG NEF 400 (CNC - Lathe) 2 axis universal lathe with C-axis and driven tools

Swing diameter over bed: 385 mm

Cross travel: 255 mm

Tool path: 700 mm

control: Siemens 840D

Portal milling machine FS 10-dynamic

Verfahrwege / working range

X = 5.900 mm

Y = 1.670 mm

Z = 850 mm

pivot axes: A = +/- 110° C = +/- 400°

milling spindle: max. 12 KW / max. 24.000 U/min / HSK 63F

Feed linear axes

X = 40 m/min

Y/Z = 30 m/min

CNC - Measuring machine Zeiss CONTURA 10/16/6 active

range: 1.000 x 1.600 x 600 mm

measuring acc. ISO 10360-2 for VAST XT gold, VAST XTR gold

E0 = (1,7 + L/350)µm, PFTU = 1,7 µm

Permissible temperature range for specification

18 - 22 °C

Scanning acc. ISO 10360-4 für VAST XT gold, VAST XTR gold

for VAST XT gold, VAST XTR gold

MPE_THP = 2,8 µm in 40 s

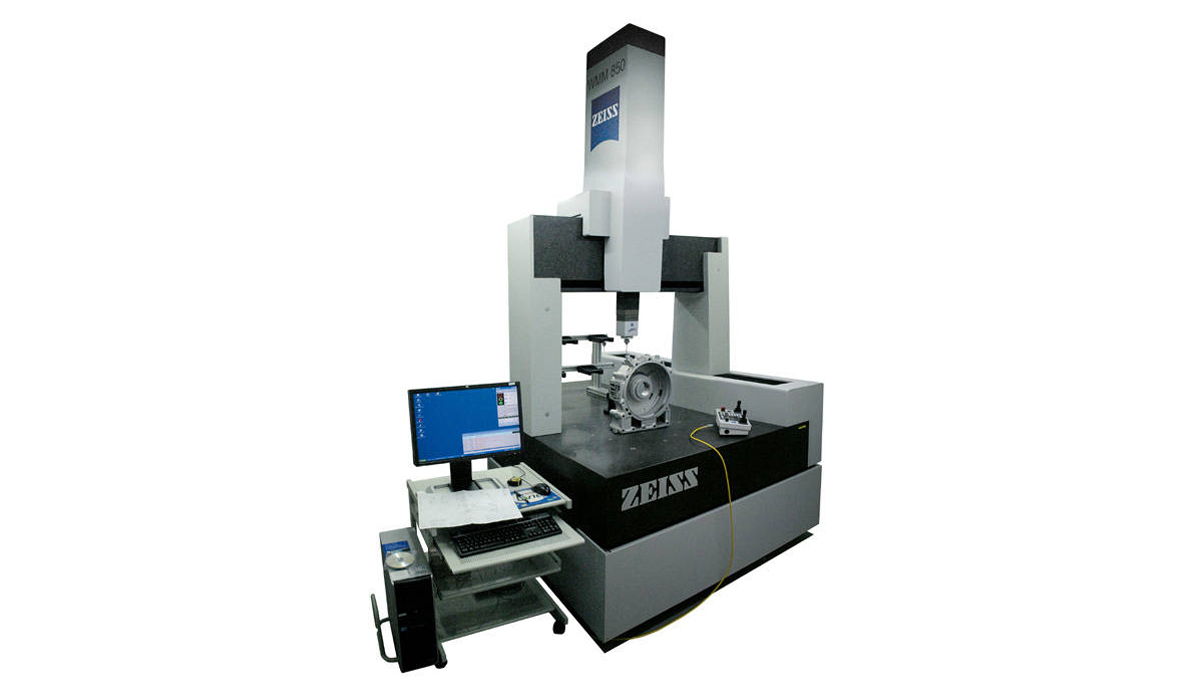

CNC - Measuring machine KMG Zeiss MC 850

Software Calypso

range: 1.000 x 800 x 600 mm

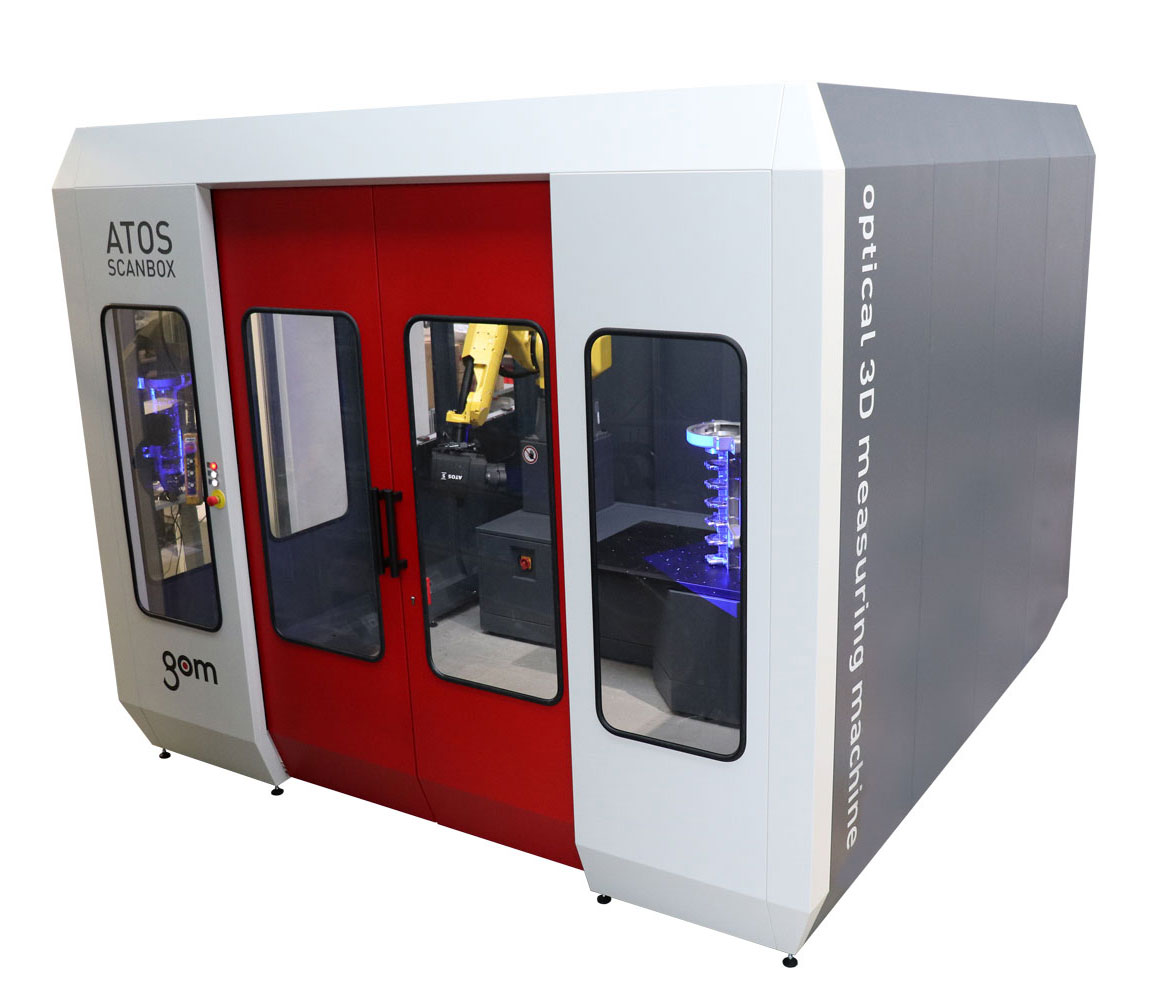

Optical measuring system GOM ScanBox 5120

dimensions: 3300 × 3300 × 2700 mm

Power supply: 200 – 500 V (3-phase, 16 A)

Rotary attachment: Ø 2000 mm

Load on attachment: 500 kg

Entrance: sliding door with security door switch

Opening width: 1400 mm

Loading concept: manual, trolley, pallet truck

Sensor Compatibility: ATOS Capsule, ATOS Triple Scan, ATOS 5

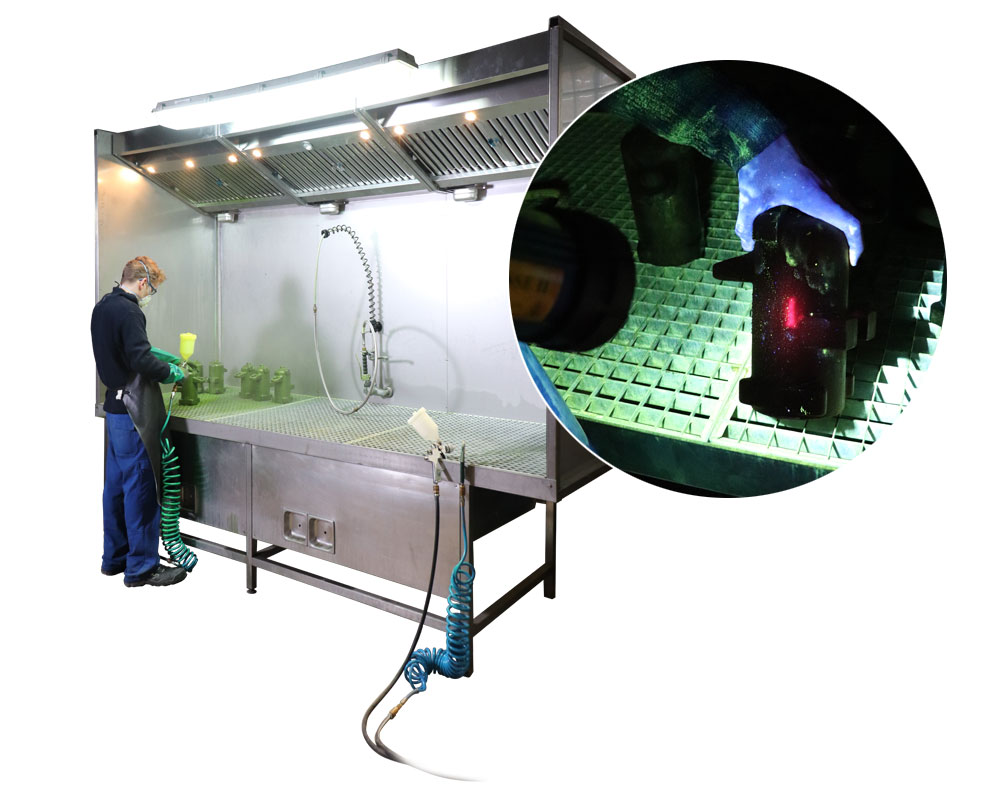

FPI Testing

We conduct

FPI (Fluorescent Penetrant Inspection) according to

DIN EN ISO 3452-1. Our personnel is trained and certified according to

DIN EN 4179 (Aerospace).

Pressure-tight test system

We have 2 pressure density testers to inspect components for leaks.

parts laundry

Parts washing for cleaning your components.

Laser welding system

Name: HTS Mobile 300 W

Working range: 400/700/570

Laser power: 300 W

Pulse peak power: 13 KW

Laser source: YAG lamp laser

Cooling: water + air

Welding under shielding gas: yes

CNC: yes

X-ray system

to assess the internal properties of the casting.

Spectral analysis

to determine the alloy components during the goods receipt inspection and at the cast component and for the monitoring of special magnesium melts in the production process.

Tensile testing

to determine the mechanical characteristics by tensile tests at the test bar.